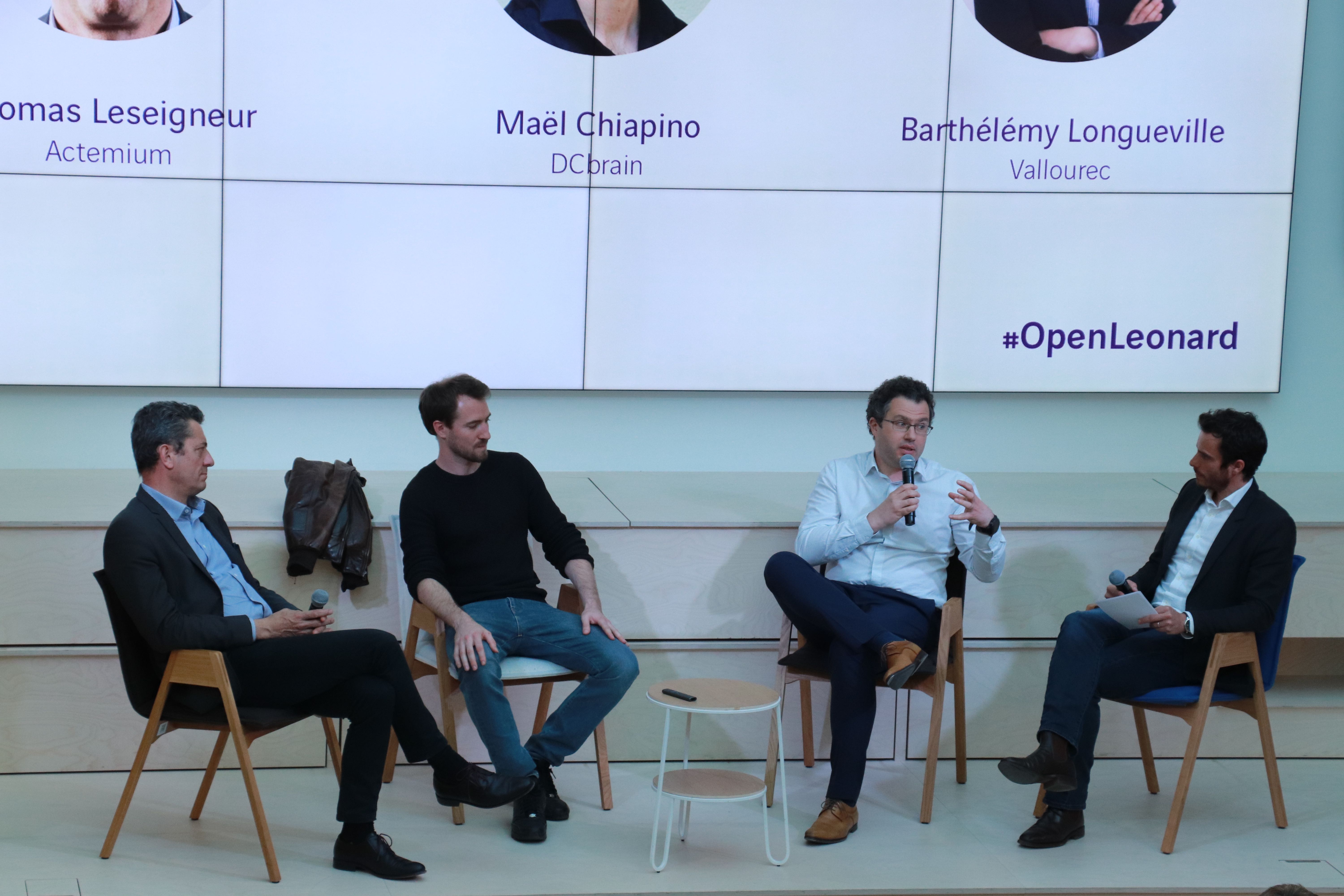

Our fourth gathering under Leonard:Paris’ glass roof focused on artificial intelligence. We brought together experts and industrials to see just how AI can add value in industry. In this sector, where maintenance and process optimization are key, many see AI as a promising way to boost efficiency, cut costs and detect problems that could hinder production. The question is, can AI really give industry a boost, or is it just a technological mirage? This article looks back at our panel discussion on May 15th.

Behind AI, the data and the humans

Though the appetite for AI is real, many potential industrial clients are still sure exactly how it can be used. Thomas Leseigneur, Innovation Manager at Actemium, believes they should start by asking “What do we want to do”? Jean-Baptiste Léger, Managing Director of Predict, a company that specialises in e-maintenance of industrial facilities, said “People want and know they have to move towards AI, but you can’t do it any old how”.

Any attempt to optimize a manufacturing process using AI requires prior modelling of the system’s behaviour to better understand it. This vital preliminary work is based on the data provided by the client. The availability and quality of this data is key and significantly impacts the project’s outcome. “It’s difficult to develop a solution if you don’t have the data, it’s an impediment”, explains Maël Chiapino, Data Scientist with DCBrain, a company that offers an AI-powered solution for physical networks. “For the model to work, you have to analyse the system, collect the data and then cleanse it”. Processing, selecting and storing the relevant data to feed a model is a significant undertaking. It is a core part of the work carried out by the French Alternative Energies and Atomic Energy Commission (CEA), represented by Lorène Allano. And it is a job that is done by real humans.

A super assistant that boosts performance

Once this process is complete, the results obtained with AI and presented by our various speakers, go well beyond simply optimizing a process. Barthélémy Longueville, CDO at Vallourec, the world leader in tubular solutions for the energy and industry sectors, has developed in-house solutions for the company’s own production line. “Understanding the production model, enabled us to change the manufacturing process, cut costs and increase our margin. But it’s also a differentiating factor for our clients” who can now follow the manufacturing process in real time. Some production sites go even further: at one of Vallourec’s steelworks, the processes have been optimized so the machine takes its decisions in under a minute. In this case, the impact of machine on the production line is almost like that of an automatic pilot.

Above all, AI must remain a decision-aiding tool for manufacturers, because though the technologies exist, they are definitely not yet able to replace professionals and take decisions for them. Jean-Baptiste Léger believes that AI should be used to learn from a system’s limitations and better suggest improvements to its architecture. Thomas Leseigneur shares this view, “artificial intelligence improves performance, but you need the humans at the system’s core to envision the future of the industry. The technology can’t replace the people.”

We will continue to discuss AI at Leonard:Paris. Join us on May 21st at 9am to meet the startups making the AI leap with their innovative solutions!