If you’ve previously looked to buy or rent a property, you’re probably already pretty familiar with the process. You tick several boxes according to your needs, and adjust the cursor to match your price range and the number of bedrooms. Then the software program works its magic to make the results corresponding to your needs appear. This parametric function is widely-used in search engine tools, which gives results according to predefined variables. In the future, this could also become widespread amongst designers and constructors, automatically proposing plans depending on light, shape or surface use restrictions. Technology is relying on artificial intelligence and deep learning, and harnessing learning software that can lean on a large back catalogue of past projects to autonomously improve. For the construction world, the rise of parametric design today creates opportunities for optimization and simplification, showing that this trend could transform the whole industry value chain.

Aiding design, supporting creativity

Today, generative design and parametric design are mainly used during the design phase. There are numerous arguments for this, for example, these methods enable the architectural design and structural analysis stages to be brought drastically closer together. Take the Z15 tower in Beijing, which was built in a seismic zone: parametric simulations have enabled increased dialogue between engineers and architects, reducing the final decision-making time to just several days, rather than weeks of going back and forth.

Automation technology also makes it possible to envisage speeding up radically the exploratory phase and results optimization. Now Autodesk is taking a look into the issue, in a collaboration with Dutch construction company Van Wijen. As part of a residential project in Alkmaar, the two companies presented a design process which is closer to urban programming rather than traditional architecture: once the factors have been defined and verified, the software determines all the layout possibilities in order to help “human” designers make the best decisions.

Generative solutions raise one important question: what place does creativity have in all of this? While production and construction standardization may first spring to mind, others see it as a way of avoiding using traditional methods. According to the artists’ collective Obvious, AI is a “new tool that enables us to increase humans’ creative potential.” For Baker Baynes, generative design is initiating the change from being a creator to a curator…

Construction optimization tool

The growing influence of generative and parametric methods are knocking down more and more walls in the design and construction phases. Construction procedures becoming increasingly automated is just a natural response to the change in the way designers now work.

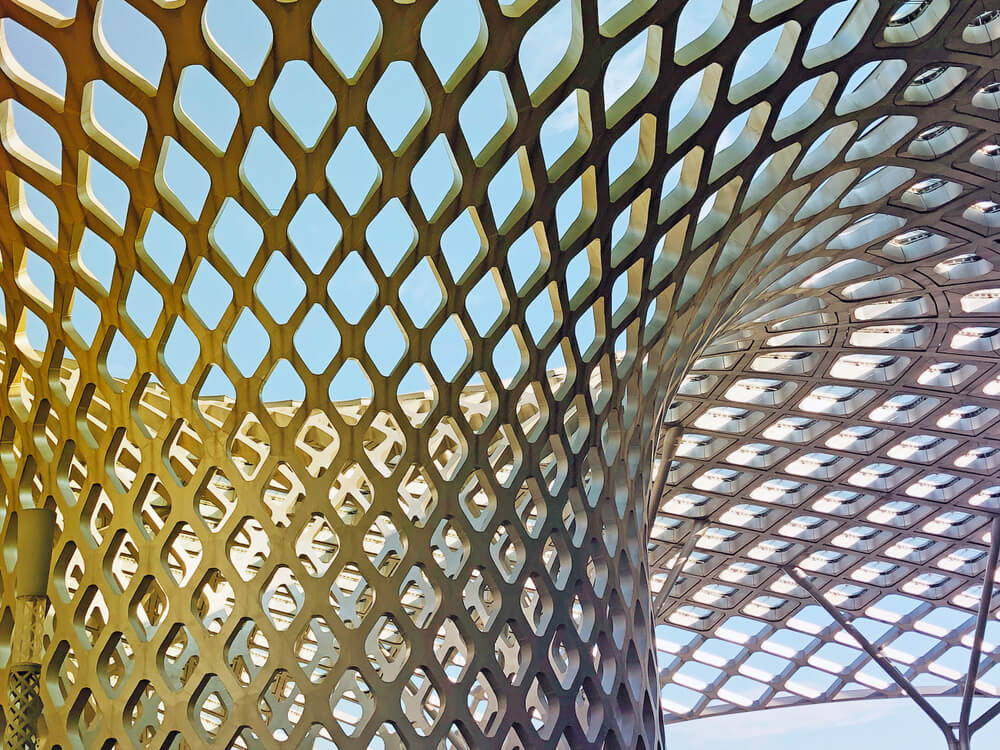

In the constant search for optimization, generative algorithms are coming up with complex forms influenced by the organic, just like the Hangzhou Tennis Center in China, Absolute Towers in Canada or even the famous Burning Man Festvial “temple”, designed by French architect Arthur Mamou-Mani. These new ideas entail new construction methods, such as 3D concrete printing which can create outstandingly complex objects. “There’s no point in using 3D printing to redo what can be done with concrete panels,” explains Romain Mesnil, head of the platform Build’In at the École des Ponts. As we wait for 3D printing to fully mature, all that remains is to invent construction procedures capable of accommodating this new complexity….

Generative design also plays a role in the actual design of a building site itself. The Crane Position Optimization project, lead by Dieter Vermeulen, uses algorithms to try and determine the most profitable location to put a crane. It’s a method that could also be applied to lorry routes, to machine use and to all procedures inherent to a building site.

Algorithmic foresight in building operations

Generative design’s contribution could extend well beyond construction, but also to maintenance and operation cycles. Michael Ørsted, head of the Technical Knowledge and Data department at Copenhagen airport, explains that the method goes particularly well with the emergence of the “Digital Twin” concept. It enables the user to calculate the best scenarios in digital double before making the necessary modifications to a building. If Ørsted develops the the toilet size model according to their use, the method can be applied to all of the building’s functions. It’s a way of making spaces live and evolve according to their function in a truly data-driven logic.