Ultra-fast charging stations for highway rest areas

The star of the latest Paris Motor Show, electric vehicles are stalled in their roll-out due to the challenge posed by long-distance travel. The subsidiary owned by VINCI Autoroutes and VINCI Energies, in partnership with Eurovia, assists automakers seeking to develop ultra-fast charging stations on the VINCI Autoroutes concession network, with support covering every step from the initial study and general contracting, to construction and maintenance. This expertise is already shaping the future of filling stations, which will be equipped with 350 kW HPC (high power charge) stations that can recharge an electric car in just 20 minutes.

As electric vehicles gradually increase their range to match gas-powered cars, the Easy Charge offer meets the needs of automakers like Ionity, a joint venture notably combining BMW, Mercedes-Benz and Ford, who teamed up to create a network of HPC stations. The brand opened two charging stations on the network’s rest areas near Angers and Tours, with 30 further stations set to open in 2019. Soon there will be no reason not to drive an electric car!

Digitization of the built environment, the foundation of the digital transformation in construction

Ushering in a small revolution in construction, BIM applies to more than just buildings: digitization can facilitate the operation of all sorts of infrastructure. “This digital twin simplifies operations for the concessionaire by enabling cross-sectional cuts or extraction of 3D sections with extreme precision: each measurement is accurate to within 2.5 cm”, declares Thomas Nallet, operations manager at Sixense Mapping, part of VINCI Construction’s Sixense Group specializing in digitization and data processing.

When it comes to digitizing infrastructure, every means has its place: drones, helicopters, cars and even backpacks, equipped with imaging or Lidar (remote sensing by laser) technology to adapt to a variety of terrains. Both static and dynamic sensors are used to digitize 2,400 km of sewers in Paris with extreme precision. This two-year exploration process, carried out by an association between two VINCI companies, SIXENSE Perazio and Campenon Bernard Régions, will help to develop a digital twin to enable virtual tours and reduce human intervention.

Exoskeletons offer a new way to improve working conditions for operators

Exoskeletons offer a solution to the safety challenges and strenuousness of certain tasks performed on worksites. With Exopush, RB3D assists workers with certain levelling operations by multiplying their strength by 5! By reducing the effort required by the task, the tool allows the operator to stand up straight and maintain safe posture.

The fruit of five years of R&D and an investment of one million euros, the exoskeleton runs on a 48-volt battery which powers an electric motor. Force sensors located on the sleeve send information to the control panel, which instantly boosts the worker’s strength fivefold, with no delay between the worker pushing the mechanism and the activation of the machine. However, worksite teams must still receive training to ensure the tool will sustainably lessen the strenuousness of their tasks. “We cannot just show up on worksites and force Exopush on operators who have developed deeply ingrained habits and customs over many years”, underlines Hervé Meunier, sales manager France. Eurovia will offer demonstrations of the two models it has acquired, in order to support operators with the changes impacting their jobs.

Robot-assistants to create more efficient worksites

When it comes to risky or repetitive operations, robots can help workers ensure safe worksites and reduce the time needed for their completion. Waste handling can become a particularly strenuous and time-consuming task on a flushing site. The R&D service at Neom, a subsidiary of VINCI Construction France specializing in flushing, asbestos removal, demolition and lead removal, robotized this process using a robot caterpillar able to assist an operator or complete the journeys necessary to evacuate waste on its own. The prototype was tested on the site of the future headquarters of BNP Paribas, on Boulevard des Italiens, where it evacuated 1,000 metric tons of waste.

“Asbestos risks have also made automation even more pertinent and necessary,” recalls François Tesseire, R&D engineer at Neom. For this reason, the R&D entity developed robots able to perform asbestos removal without the intervention of a human operator, such as its sandblasting robot which is used to remove asbestos products from submarine hulls. This first prototype will be tested in January at an asbestos removal site for submarines.

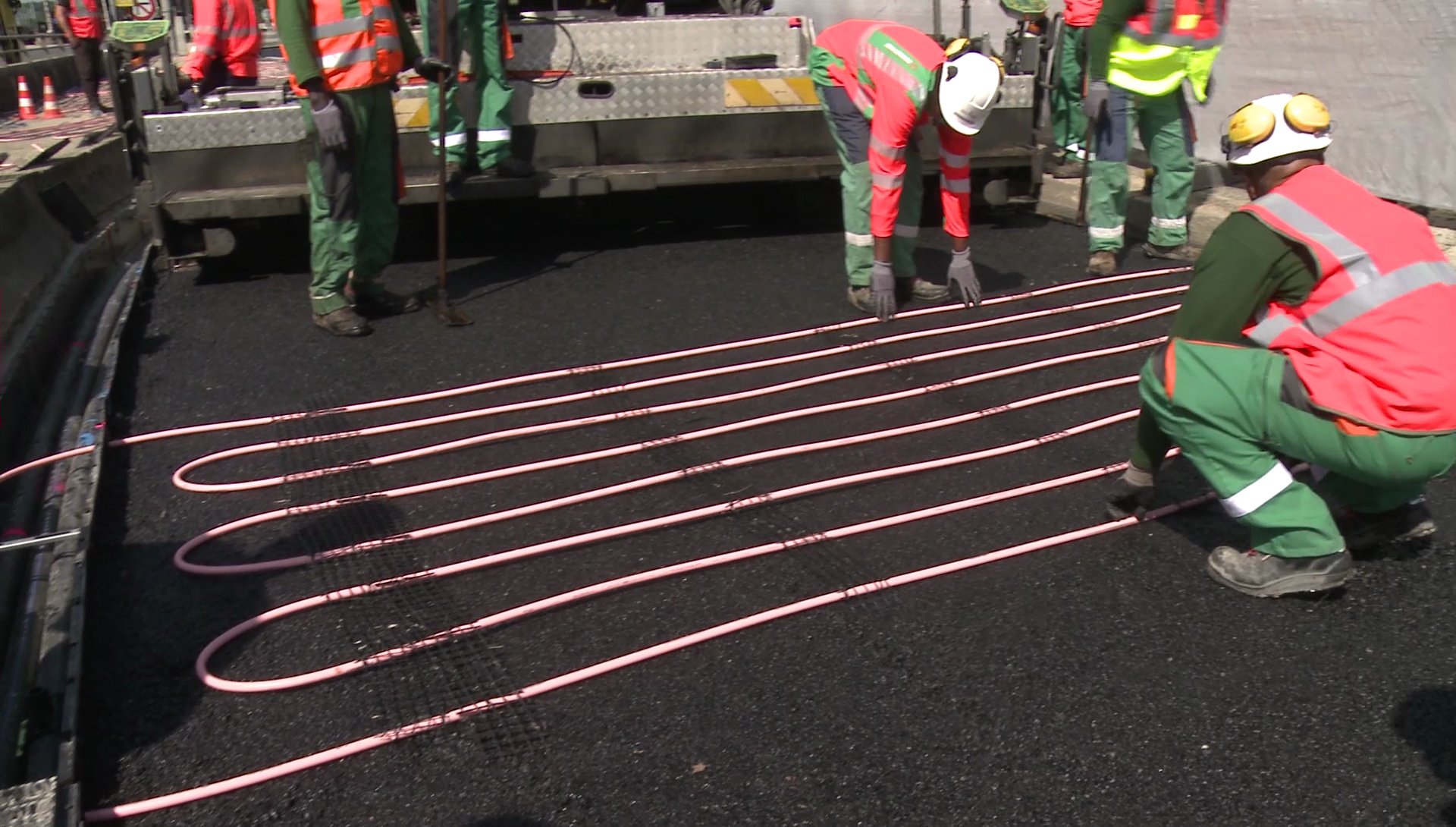

Melting snow and ice with heated roads

Infrastructure is starting to offer innovative new features. Power Road technology, developed by Eurovia with CEA Tech, absorbs solar energy and then transfers it to nearby structures. The system could de-ice bridges during frosts, or deliver basic heat to public facilities (such as swimming pools, offices of eco-districts). In summer, heat absorption could cool the roads, and reduce the heat island effect.

To learn more about this new technology, read our article about the future roads.